Exploring how robotic vision influences advanced production techniques and quality control

The Significance of an Optical Fibre Diameter Analyser in Keeping Market Specifications

The value of an Optical Fibre Diameter Analyser can not be overstated in the context of market requirements. This innovation guarantees precise measurements, which are important for optimal signal transmission and decreased attenuation. By spotting incongruities early, manufacturers can support strict quality assurance measures. Nonetheless, the effects of these measurements extend beyond compliance. Uncovering the more comprehensive effect on system performance reveals complexities that warrant additional exploration.

Recognizing Optical Fibre Diameter Analysis

Optical fibre diameter analysis plays an essential duty in guaranteeing the performance and dependability of fibre optic systems. Precise measurement of fibre diameter is essential, as it directly affects signal transmission efficiency and general system stability. Variants in diameter can cause enhanced depletion, decreased bandwidth, and greater susceptibility to ecological factors.

By utilizing precise measurement strategies, producers can keep strict quality assurance, making certain that fibres fulfill industry requirements. This evaluation also promotes the identification of flaws or inconsistencies during manufacturing, permitting for timely restorative actions.

In addition, understanding the diameter criteria aids in the option of ideal connectors and fittings, consequently boosting compatibility within the network. Generally, thorough optical fibre diameter analysis is a foundational aspect of fibre optic innovation, underpinning innovations in telecoms, information transmission, and numerous applications throughout different industries.

Secret Functions of Optical Fibre Diameter Analysers

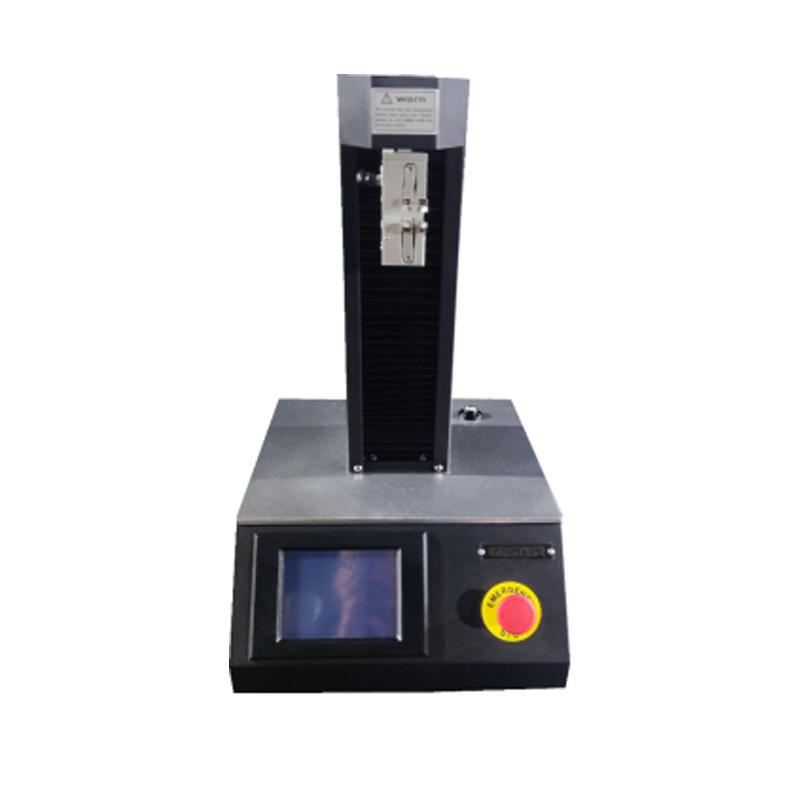

Optical fibre diameter analysers are geared up with a number of vital attributes that improve their performance. Remarkable amongst these are accuracy dimension capabilities, which assure exact analyses, and real-time monitoring features that provide immediate feedback throughout the evaluation procedure. Additionally, a straightforward user interface layout promotes very easy procedure, making these gadgets easily accessible to a broader series of individuals.

Precision Measurement Capabilities

When it comes to guaranteeing premium fibre production, precision dimension abilities are critical in diameter analysers. These devices use sophisticated technologies to deliver exact dimensions of fibre diameter, enabling manufacturers to keep rigorous tolerances. High-resolution optics and innovative formulas allow the discovery of min variants in diameter, crucial for generating dependable and consistent optical fibers. Furthermore, the ability to determine across a wide variety of diameters boosts flexibility, accommodating numerous production demands. The combination of calibration criteria ensures that measurements continue to be accurate with time, minimizing the danger of issues. By employing these accuracy measurement capacities, manufacturers can promote industry requirements, improve product top quality, and eventually drive customer satisfaction in the competitive fibre optics market.

Real-Time Surveillance Attributes

Real-time monitoring attributes are crucial for improving the performance and effectiveness of fibre manufacturing procedures. These capabilities allow continual assessment of optical fibre diameter throughout manufacturing, ensuring that any type of inconsistencies from specified requirements are immediately discovered. By giving instant feedback, makers can promptly readjust parameters, lowering waste and preserving high quality control. In addition, real-time tracking facilitates the identification of fads and patterns in manufacturing data, supplying useful insights for process optimization. The integration of these attributes right into optical fibre diameter analysers sustains positive decision-making, empowering drivers to respond swiftly to prospective issues. As a result, the implementation of real-time tracking not only promotes industry standards however likewise improves general efficiency and product dependability.

User-Friendly User Interface Layout

A properly designed individual interface is essential for the reliable procedure of optical fibre diameter analysers. Such interfaces prioritize simpleness and access, permitting individuals to navigate the system effortlessly. Trick functions commonly include intuitive food selections, clear visual representations of data, and customizable setups to fit various customer preferences. Real-time feedback systems enhance the customer experience by offering instant insights into dimensions. In addition, efficient mistake messaging guides customers in fixing issues swiftly, decreasing downtime. The unification of touchscreens and responsive layouts even more facilitates communication, making it easier for technicians to operate the analyser in varied atmospheres. Ultimately, an easy to use interface not just improves effectiveness but likewise improves the total accuracy of the measurements, adding to market criteria in optical fibre manufacturing.

The Duty of Diameter Measurement in Quality Assurance

Diameter measurement may appear like a minor information in the production of optical fibres, it plays a substantial role in guaranteeing total top quality control. Consistency in diameter is crucial for maintaining the optical performance and structural honesty of the fibers. Variations in diameter can cause concerns such as signal loss, increased attenuation, and minimized tensile toughness, inevitably compromising the dependability of the fibre in numerous applications.

Quality assurance processes incorporate accurate diameter measurement to find defects early in production. By executing an optical fibre diameter analyser, manufacturers can determine any type of inconsistencies from defined resistances, facilitating immediate corrective activities. This aggressive strategy not only improves product top quality yet also decreases waste and minimizes manufacturing prices.

Conformity With Sector Standards and Rules

Compliance with industry criteria and guidelines is crucial for the precise procedure of an optical fibre diameter analyser. Sticking to these standards guarantees that producers preserve quality assurance throughout the manufacturing procedure. Fulfilling regulatory requirements not only enhances product dependability however likewise cultivates consumer count on.

Making Certain High Quality Control

Guaranteeing adherence to industry criteria is important for preserving the stability and performance of optical fibre products. Quality control plays a pivotal role in this process, as it includes the methodical tracking of fibre diameter to ensure consistency and dependability. An optical fibre diameter analyser is an important tool in accomplishing these quality benchmarks, giving precise measurements that assist determine discrepancies from established specs. By utilizing this innovation, manufacturers can swiftly discover and attend to any type of anomalies, making sure that items satisfy the needed performance criteria. Regular analysis via such analysers not just supports product quality yet additionally boosts client count on and fulfillment. Eventually, robust quality control actions promote an one-upmanship in the optical fibre industry, advertising long-lasting success and conformity with requirements.

Meeting Governing Requirements

As producers browse the intricacies of the optical fibre sector, conference regulatory needs comes to be important for guaranteeing product security and performance. Compliance with industry criteria not only reduces prospective risks but also boosts customer self-confidence in the products provided. An optical fibre diameter analyser plays a crucial duty in this process, enabling suppliers to verify that their items stick to defined measurements and tolerances. By using such analyzers, companies can guarantee that their optical fibres meet the strict guidelines stated by sector authorities. This aggressive strategy to top quality guarantee not just promotes conformity but likewise streamlines the production procedure, reducing the probability of expensive recalls or rejections. Ultimately, adherence to regulative standards is crucial for preserving an one-upmanship in the market.

Benefits of Accurate Diameter Measurement

Precise diameter have a peek at this website dimension plays a necessary role in the efficiency and dependability of optical fibres. Ensuring that fibres satisfy defined diameter resistances lessens signal loss and makes the most why not check here of transmission effectiveness, directly impacting overall system performance. This precision is vital in keeping ideal light breeding, as also small variances can cause boosted attenuation and decreased optical signal quality.

Exact dimensions improve compatibility between components in fibre optic systems, promoting smooth combination and decreasing the risk of failings. Constant diameter measurements additionally contribute to improved production processes by recognizing possible flaws early, consequently decreasing waste and reducing manufacturing costs.

Integrating Optical Fibre Diameter Analysers Into Production

Incorporating optical fibre diameter analysers right into production processes boosts the capacity to keep rigid quality assurance steps. By employing these analysers, suppliers can attain precise and regular dimensions of fibre diameters, which is vital for ensuring product performance and integrity. The combination process commonly entails placing analysers at vital factors along the manufacturing line, allowing real-time tracking and immediate comments on diameter variations.

This aggressive method enables fast modifications to the manufacturing specifications, decreasing the threat of problems and waste. Additionally, the information accumulated can be made use of for statistical procedure control, adding to continual enhancement initiatives. Operators are equipped with workable insights that promote informed decision-making pertaining to product usage and production strategies. Ultimately, the unification of optical fibre diameter analysers not just enhances item high quality but additionally sustains compliance with sector requirements, reinforcing a firm's online reputation for quality in the competitive optical fibre market.

Future Fads in Optical Fibre Measurement Technology

Arising developments in optical fibre dimension innovation are positioned to reinvent the industry. The unification of fabricated knowledge and artificial intelligence is expected to boost accuracy and performance in diameter analysis. These modern technologies allow real-time information processing, permitting immediate adjustments throughout production, consequently minimizing waste. Additionally, the development of non-contact dimension strategies guarantees a decrease in physical interaction with fibres, maintaining their integrity.

Additionally, miniaturization of measurement devices is anticipated to lead to more mobile and user-friendly services, assisting in on-site evaluations. robotic vision. Integration with IoT systems will enable remote monitoring and data collection, fostering improved anticipating maintenance and quality assurance

As markets increasingly require greater performance standards, the evolution of optical fibre measurement tools will play an essential function in satisfying these expectations, making sure that suppliers can continually deliver top notch products while adhering to rigorous governing requirements.

Regularly Asked Inquiries

How Typically Should Optical Fibre Diameter Measurements Be Performed?

Regularity of optical fibre diameter measurements normally depends on production quantity and high quality needs. Routine checks, typically everyday or regular, assist guarantee regular quality and adherence to specifications, lessening possible problems in fibre manufacturing processes.

What Are the Normal Expenses of Optical Fibre Diameter Analysers?

The normal costs of optical fibre diameter analysers vary extensively, varying from a number of thousand to tens of countless bucks, depending upon features, accuracy, and manufacturer, affecting choices for companies buying quality measurement modern technology.

Can Diameter Analysers Be Calibrated On-Site?

Diameter analysers can commonly be adjusted on-site, enabling for immediate changes to ensure precision. Nevertheless, the particular treatments and demands might vary depending on the supplier's guidelines and the modern technology utilized in the analyser.

What Kinds Of Fibres Can Be Calculated With These Analysers?

Optical fibre diameter analysers can gauge numerous fibre kinds, consisting of single-mode, multi-mode, specialized, and large-core fibres. Each kind needs details calibration setups to ensure exact go to these guys and dependable diameter measurements throughout the manufacturing process.

Exist Details Upkeep Needs for Diameter Analysers?

Diameter analysers require regular calibration to guarantee accuracy, along with routine cleansing to stop debris accumulation. Additionally, checking software updates and examining mechanical elements add to their optimal performance and durability in measuring fibre diameters efficiently.